| Availability: | |

|---|---|

| Quantity: | |

Y-23

QingQuan

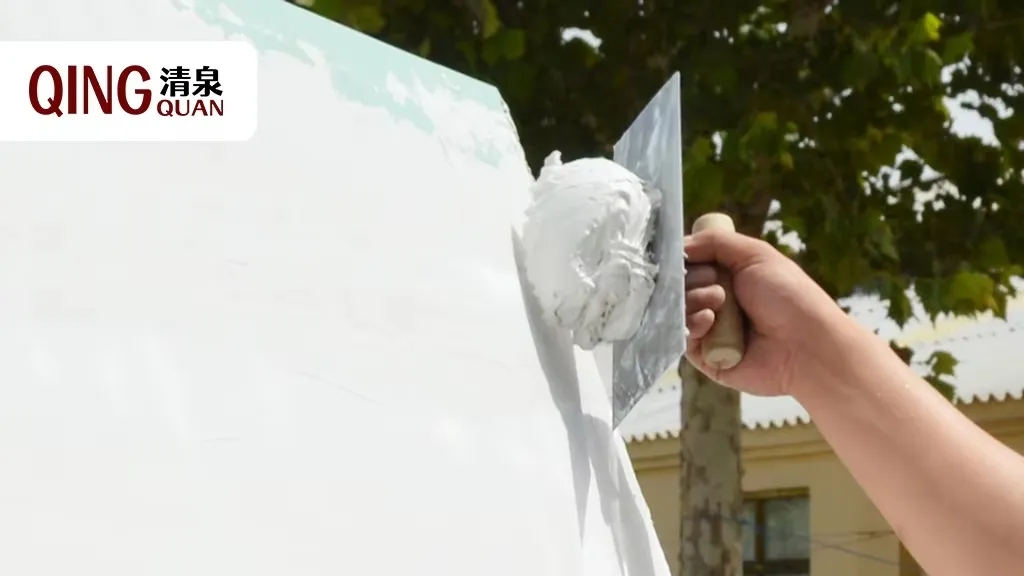

QingQuan Cellulose is a specialized manufacturer of high viscosity Hydroxypropyl Methyl Cellulose (HPMC), a key additive optimized for putty applications. This grade of HPMC significantly increases the body and thixotropy of putty, preventing sag on vertical surfaces while ensuring excellent water retention for extended workability and a superior, durable finish that resists cracking.

Package Size 110.00cm * 110.00cm * 120.00cm

Package Gross Weight 600.000kg

Product Introduction (Profile)

Hydroxypropylmethylcellulose (HPMC) is a nonionic cellulose alkyl hydroxyalkyl mixed ether obtained from cellulose by alkalization, etherification, neutralization and washing processes.

Qingquan Indicators | QINGQUAN - HPMC | |||

ME(60HPMC) | MF(65HPMC) | MJ(70HPMC) | MK(75HPMC) | |

Methoxy content /% | 28.0-30.0 | 27.0-30.0 | 16.5-20.0 | 19.0-24.0 |

Hydroxypropyloxy content/% | 7.5-12.0 | 4.0-7.5 | 23.0-32.0 | 4.0-12.0 |

Gel temperature /ºC | 58.0-64.0 | 62.0-68.0 | 68.0-75.0 | 70.0-90.0 |

Ash /% | ≤1.0 | |||

Moisture /% | ≤5.0 | |||

pH value | 4.0-8.5 | |||

Viscosity (2% aqueous solution, 20°C)/mPa-s | (ND-J)10000-200000 | |||

Appearance | White powder | |||

Surface tension (CCL4)/(X10-3N/M2) | 10 | |||

HPMC has a wide range of roles in construction materials, it can be applied to masonry mortar, plastering mortar, stucco, plastering paste, adding a small amount of HPMC to the material will result in a great improvement in these properties. In cement and gypsum based, plasters, the moisture retention effect of HPMC will result in high bond strength and hardness of the plaster after curing.

High water retention can make the cement fully hydrated, significantly increase the bond strength, but also appropriate to improve the tensile bond strength and shear bond strength of hardened mortar, but also significantly improve the ease of use and lubricity, greatly improve the construction effect, improve work efficiency. When cement mortar is used, it is important to ensure good water retention because of the strong water absorption of bricks and wall surfaces, coupled with the high sand content of the mortar. Otherwise, bricks etc. can easily adsorb the water out of the mortar, making the mortar partially water-loss and the cement difficult to fully hydrate. The bond strength of mortar composed of sand-lime-cement is very low, and after adding cellulose ether, the bond strength increases significantly, and the tensile bond strength and shear bond strength will be relatively high even if there is a significant eccentric load or horizontal load occurs.

Suitable for water-resistant putty In water-resistant putty, the main role of cellulose ether is to retain water, improve adhesion as well as lubricity, to avoid cracks or powder phenomenon caused by rapid loss of water, and at the same time to enhance the adhesion of the putty to reduce the phenomenon of hanging in the construction, so that the construction of the smoother, less labor, and enhance the controllability. | Suitable for plastering In gypsum series products, cellulose ether mainly plays the role of water retention, thickening, lubrication, etc. It also has a certain retardation effect, which can solve the problems of bulging and cracking in the process of construction, and the problem that the initial strength cannot be reached, and prolong the working time. |

Suitable for use with interfacial agents HPMC is mainly used as a thickener, which can improve the tensile and shear bonding strength, improve the surface coating, enhance the adhesion and bonding strength. | Suitable for tile adhesives HPMC has a relatively high water retention effect, in the construction, do not have to soak or wet the back of the tiles, significantly improve the bonding strength, slurry fine, uniform, can be constructed over a long period of time, construction is convenient. |

Suitable for slurry spraying Spray slurry with cellulose is suitable for all kinds of protective works on internal and external walls of buildings, roofs, floors and tunnels. Cellulose can form a certain combing effect in the spray slurry material, increasing the cohesion and adhesion of the material, thus effectively overcoming the cracking problem of the material itself, and improving the impermeability and durability of the sprayed layer. | Suitable for daily-use chemicals Commonly used in cosmetics, shampoos, shower gels and other daily-use chemicals.HPMC has good thickening properties and can be thickened by combining with water molecules to form a colloid.HPMC can increase the consistency of the product, making it easier to apply and use. It has excellent moisturizing properties and can absorb and retain water molecules. |

Suitable for caulking The addition of HPMC provides good edge bonding, low shrinkage and high abrasion resistance, protecting the base material from mechanical damage and avoiding the negative effects of water penetration on the building. | Suitable for self-leveling cement mortar Low viscosity HPMC can be added into self-leveling cement mortar to improve the good fluidity of the mortar, improve the construction efficiency, high surface strength after drying and low shrinkage. |

Suitable for latex paints In the paint industry, HPMC can be used as film-forming agent, thickener, emulsifier and stabilizer, so that the paint film has better abrasion resistance, uniformity, adhesion, improve the surface tension and PH value stability. | Suitable for gypsum decorative materials As gypsum products have the advantages of light weight, heat insulation, fire resistance and adjustable indoor temperature. After adding HPMC, it can make gypsum hydrate completely, ensure enough bonding force and prevent cracks. |

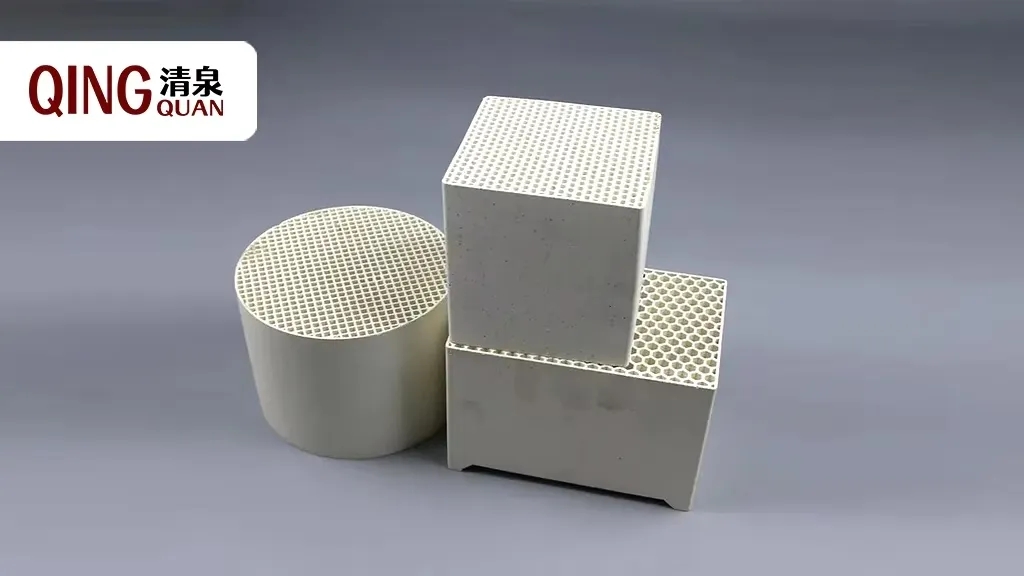

Suitable for ceramic heat storage materials Adding cellulose ether to new ceramic heat storage materials can improve the lubricity and moisture retention of detachment during model manufacturing, making them less prone to deformation and serving to improve strength. | Suitable for oil drilling fluids Cellulose ether can be used as gel polymer, fluid loss prevention agent and friction reducer to improve oil recovery . It makes the mud form a stable suspension system.The application of HPMC in oil drilling is mainly to improve the performance of mud, improve the drilling efficiency and reduce the pollution of mud, so as to achieve the purpose of improving the drilling effect. |

Qualification Certificate

Our prices may vary due to availability and other market factors. We will send you an updated price list after you contact us for more information.

Yes, we can provide most of the documents including origin analysis/conformity certificate and other required export documents.About after-sales serviceWe can guarantee our materials and technology with perfect after-sales service to make you satisfied with

our products.

The shipping cost depends on the pickup method you choose. Express shipping is the fastest, but also the most expensive way.Transportation is the best solution for high volume shipments. We can only give you the exact shipping cost once we know the details of the quantity, weight and method. Please contact our sales staff.

Please contact our sales staff for a one-on-one answer.

Application of Building Specific Thickening Agent Mortar Additive Coating HPMC

Characteristics of High Quality Ceramic Tile Adhesive Putty Cement Additive Mhec

Methods for Identifying The Quality of Redispersible Latex Powder

Market Status of HEMC Manufacturers for Industrial Building Materials in China

Home | About Us | Products | News | Contact Us | Keyword Index | Keywords | Product Category | Innovation | Insights | Solutions