Views: 0 Author: Site Editor Publish Time: 2025-06-20 Origin: Site

HPMC and HEMC belong to the family of cellulose ethers, which are widely used in industries such as food, pharmaceuticals, cosmetics, coatings, and, most importantly, building materials. These cellulose ethers are known for their solubility, viscosity, stability, non-toxicity, and excellent water retention properties.

HPMC is synthesized from refined cotton or wood pulp through a series of chemical reactions, including alkalization, etherification with methyl chloride and propylene oxide, neutralization, purification, and drying. The molecular structure of HPMC includes methoxy (-OCH₃) and hydroxypropyl (-OCH₂CHOHCH₃) groups, which influence its solubility, water retention, and gelation properties.

Thermal gelation behavior Non-ionic nature, preventing interactions with metal salts High mold resistance Excellent thickening, emulsification, adhesion, and water retention

HEMC is produced using a similar process to HPMC, but ethylene oxide is used instead of propylene oxide during etherification. This modification introduces hydroxyethyl (-OCH₂CH₂OH) groups, making HEMC more hydrophilic and thermally stable compared to HPMC.

Higher gel temperature than HPMC Superior water retention under high-temperature conditions Excellent thickening, emulsification, and adhesion properties

The different substituents in HPMC and HEMC influence their performance. The methoxyl (-OCH₃) and hydroxypropyl (-OCH₂CHOHCH₃) content in HPMC typically ranges from 16% to 30% and 4% to 32%, respectively. Meanwhile, HEMC contains 22%-30% methoxyl and 2%-14% hydroxyethoxyl (-OCH₂CH₂OH). These variations affect water retention, viscosity, and gel temperature.

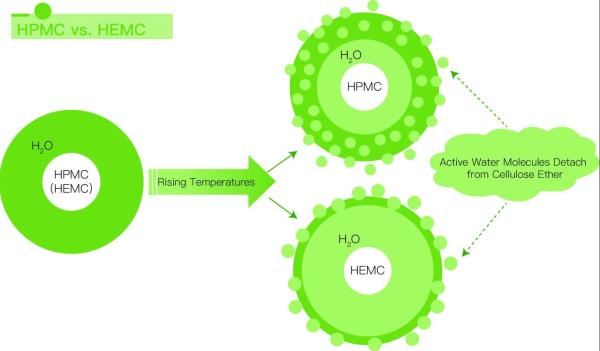

Gel temperature is a critical property in construction applications. The gel temperature of HPMC ranges from 60°C to 75°C, while HEMC exhibits a higher gel temperature of 75°C to 90°C, making it more suitable for high-temperature environments.

The ratio of methoxy to hydroxypropyl groups in HPMC determines its performance. A high methoxy content enhances water solubility but lowers the gel temperature, while increasing hydroxypropyl content raises the gel temperature but reduces surface activity.

In contrast, HEMC’s hydroxyethyl groups improve its water retention and thermal stability, making it preferable for use in high-temperature regions.

Both HPMC and HEMC function as water retention agents, thickeners, dispersants, and binders in cement-based and gypsum-based products. They help improve workability, adhesion, and durability while reducing shrinkage and crack formation.

Key benefits of HPMC and HEMC in construction applications:

Cement Mortar: Enhances cohesiveness, reduces flocculation, improves viscosity, and prevents premature drying.

Tile Adhesives: Provides better slip resistance and adhesion strength, especially in high-temperature conditions.

Gypsum Plaster: Improves workability, water retention, and crack resistance.

Emulsion Paints & Coatings: Acts as a thickener, stabilizer, and film-forming agent to enhance paint performance and durability.

HEMC outperforms HPMC in hot climates due to its higher gel temperature and superior water retention. In summer or tropical construction environments, where excessive heat accelerates cement hydration, HEMC prevents premature hardening and cracking by maintaining optimal water retention levels.

Conclusion

HPMC and HEMC are essential cellulose ether products in the construction industry, each offering distinct advantages. HPMC is widely used due to its excellent thickening and adhesion properties, while HEMC is preferred for its higher thermal stability and water retention capabilities in high-temperature environments. Choosing the right product—whether HPMC for standard construction applications or HEMC for high-temperature conditions—ensures better performance, durability, and workability in cement-based materials.

For construction professionals, understanding the differences between HPMC (Hydroxypropyl Methyl Cellulose) and HEMC (Hydroxyethyl Methyl Cellulose) is crucial for selecting the appropriate cellulose ether that meets project requirements, ensuring optimal application results.

Home | About Us | Products | News | Contact Us | Keyword Index | Keywords | Product Category | Innovation | Insights | Solutions