Views: 0 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

Our core product, construction-grade HPMC powder, offers you higher quality products and can be customized to different viscosities to meet your needs. Shijiazhuang Qingquan Cellulose Co., Ltd. is a cellulose manufacturer from China.

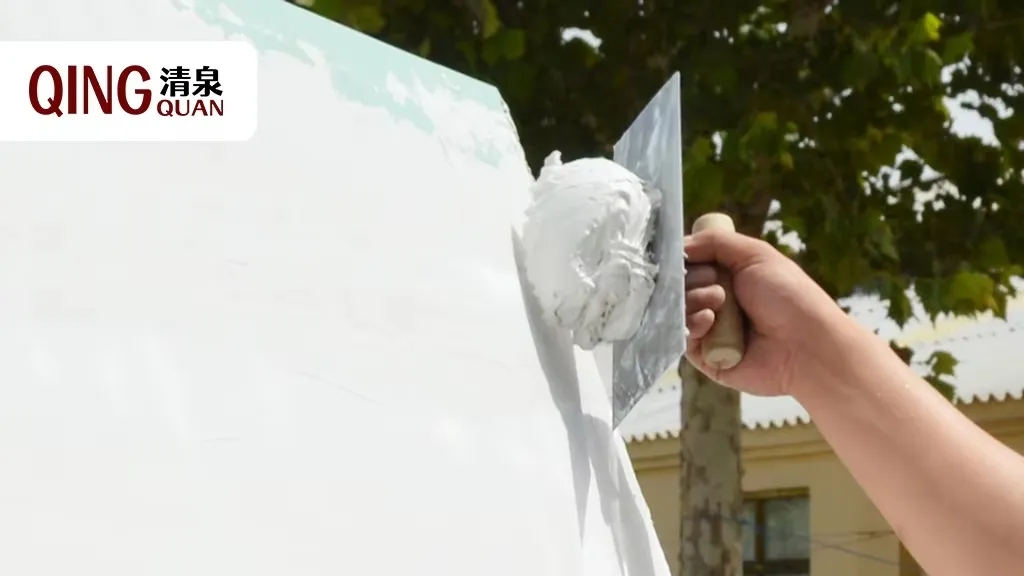

The putty powder felt heavy and sluggish when applied, making subsequent applications difficult.

Problem: The putty feels heavy and sticky on the scraper, resulting in high resistance and difficult application.

Core Causes:

Cellulose Viscosity Too High: Using cellulose with an excessively high viscosity (e.g., above 200,000 Kelvin) leads to an overly viscous putty system.

Excessive Cellulose Addition:Over-addition in an attempt to achieve better water retention.

Poor Cellulose Quality: Using "fake" cellulose blended with other thickeners (such as starch ethers or acrylics), or using cellulose with uneven polymerization, resulting in abnormal viscosity.

Solutions:

Choose the Appropriate Viscosity:For interior wall putty, a cellulose viscosity of 80,000-100,000 Kelvin is typically chosen; for exterior wall putty, which requires higher water retention, a viscosity of 100,000-150,000 Kelvin can be selected.

Precisely Control the Dosage: Under normal circumstances, the dosage of HPMC is 3‰-4‰ (i.e., 3-4 kg per ton of putty powder). Adjust slightly according to the season and local climate (temperature, humidity); slightly more in summer and slightly less in winter.

Choose pure cellulose: Purchase reputable, well-known brands of pure HPMC and avoid using inferior compound products.

Too Fast Drying, Insufficient Water Retention

Problem: The putty dries out quickly after being applied to the wall, drying out before it can be properly finished. This results in insufficient working time, poor strength, and powdering later on.

Core Causes:

Insufficient Cellulose Addition: This is the most common cause.

Poor Cellulose Quality, Low Water Retention Rate: The water retention capacity of cellulose ether is its core indicator. Inferior cellulose or adulterated products (such as those using carboxymethyl cellulose (CMC) or starch as substitutes) have extremely low water retention rates.

Harsh Environmental Factors: Applying the putty in high temperatures, strong winds, or dry weather causes excessively rapid moisture evaporation, exceeding the water retention capacity of the cellulose.

Too Low Cellulose Viscosity: Viscosity is related to water retention to some extent; cellulose with excessively low viscosity may not retain water effectively.

Solutions:

Ensure Sufficient Addition: Check the formula to ensure the HPMC addition is within a reasonable range.

Choose High Water Retention Rate Cellulose: Request a water retention rate test report from the supplier (national standard requires >90%) and choose products with high water retention rates. Improve the construction environment: In inclement weather, close doors and windows during construction to avoid drafts; if necessary, sprinkle water on the ground to increase ambient humidity.

Summer-specific formulation: In summer, consider using compound cellulose (such as a blend of HPMC and hydroxyethyl cellulose HEC), or adding a small amount of water-retaining agent to enhance water retention.

Home | About Us | Products | News | Contact Us | Keyword Index | Keywords | Product Category | Innovation | Insights | Solutions